OPTIMUS

OPTIMUS

OPTIMUS

OPTIMUS

OPTIMUS

OPTIMUS

OPTIMUS

OPTIMUS

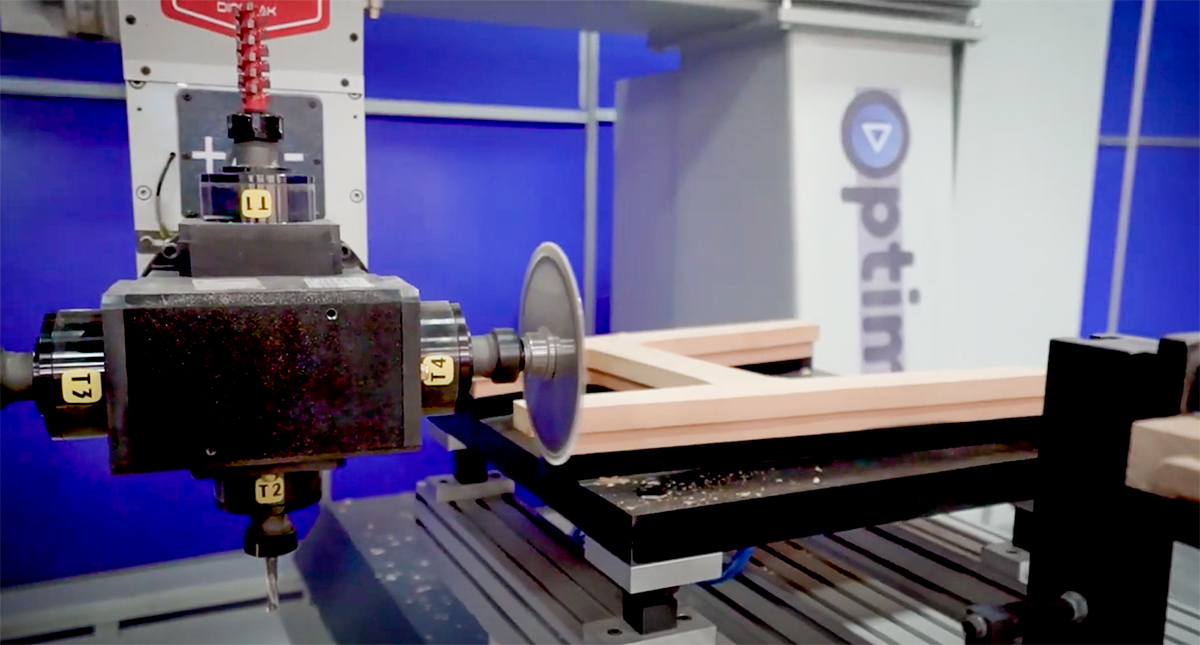

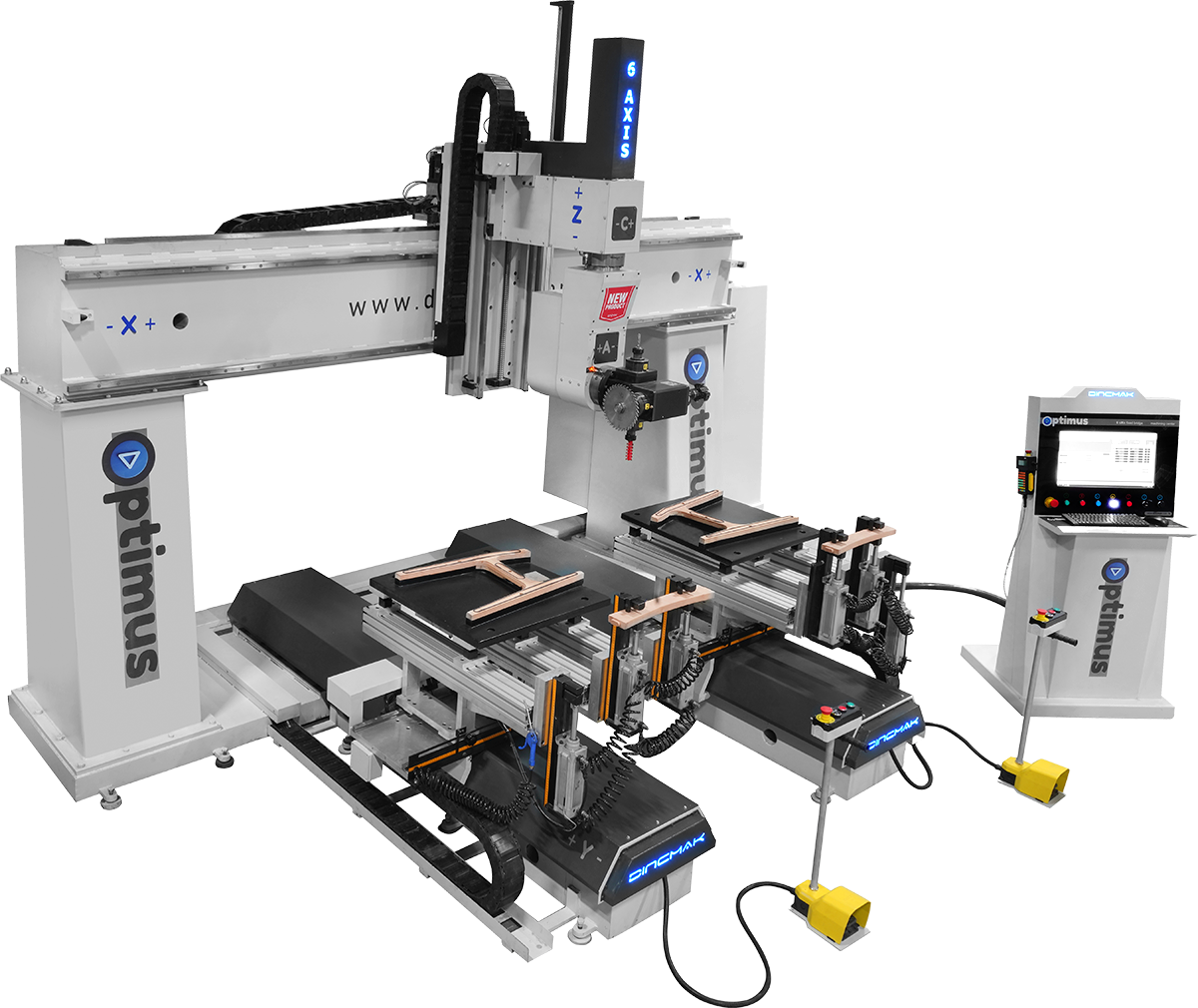

OPTIMUS is a CNC Machining Center with 6 interpolated axes and 2 independent work tables. OPTIMUS is designed to be used in the production of chairs, arm chairs, doors, windows, beds, stairs, furniture, musical instruments, etc. Pneumatic clamps holding the workpiece can be connected anywhere on the work table and can be easily adjusted according to the part length and width. A axis and C axis working without limit and it creates a fast, flexible and wide working area.

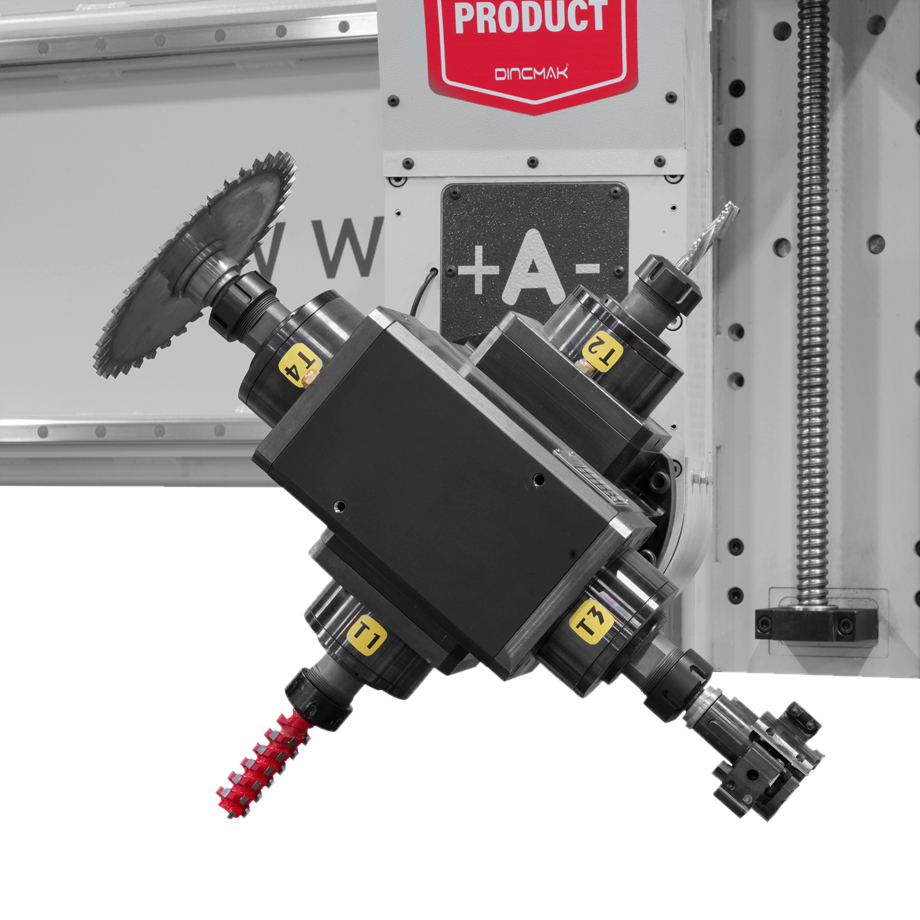

Functional Spindle

Two double-exit electric spindle with unlimited rotation. It has 7.5 kW power and 24.000 rpm rotation speed.

Working Tables

Vacuum tables have a mechanism that moves on a rail for easy adjustment to different geometries. There are fixing pins moving inside the canals for template connection.

Pneumatic Clamps

Pneumatic clamps holding the workpiece can be connected anywhere on the work table and can be easily adjusted according to the part length and width.

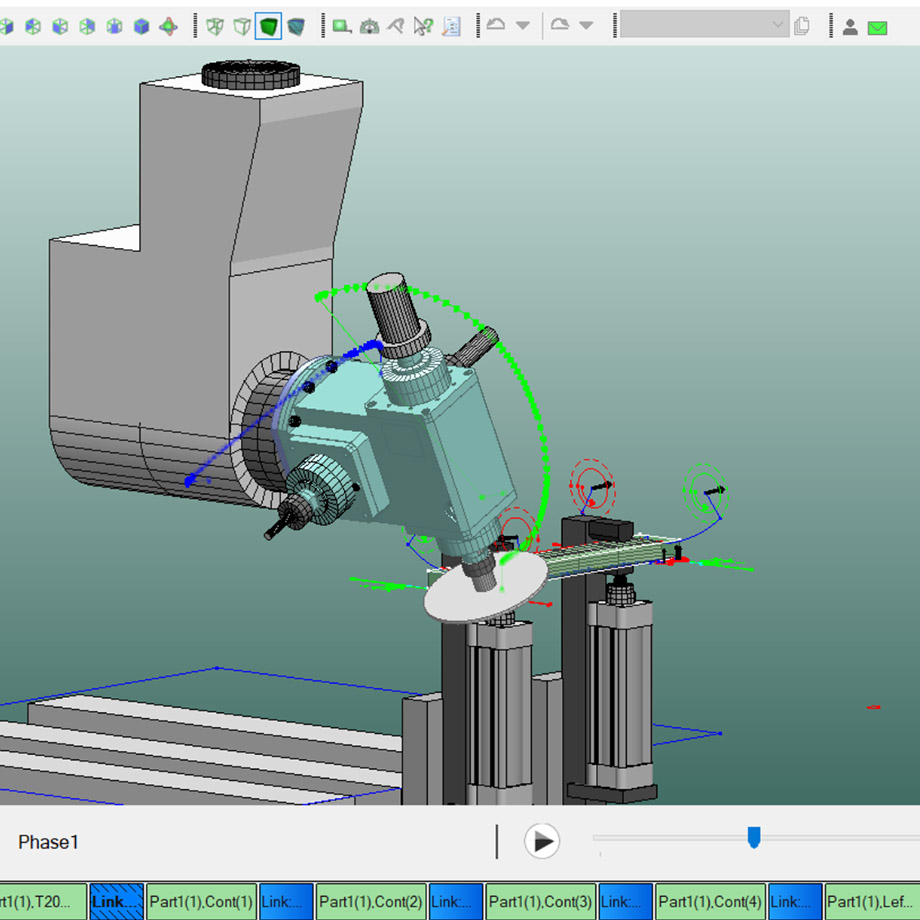

Software

It has a complete software that manages every part of the machine. It offers full control from the design stage to its placement on the work table, from collision control with 3D simulation to the optimization of all movements, and from the creation of program codes to the process paths.