DRT.D2.CNC

DRT.D2.CNC

DRT.D2.CNC

DRT.D2.CNC

DRT.D2.CNC

DRT.D2.CNC

DRT.D2.CNC

DRT.D2.CNC

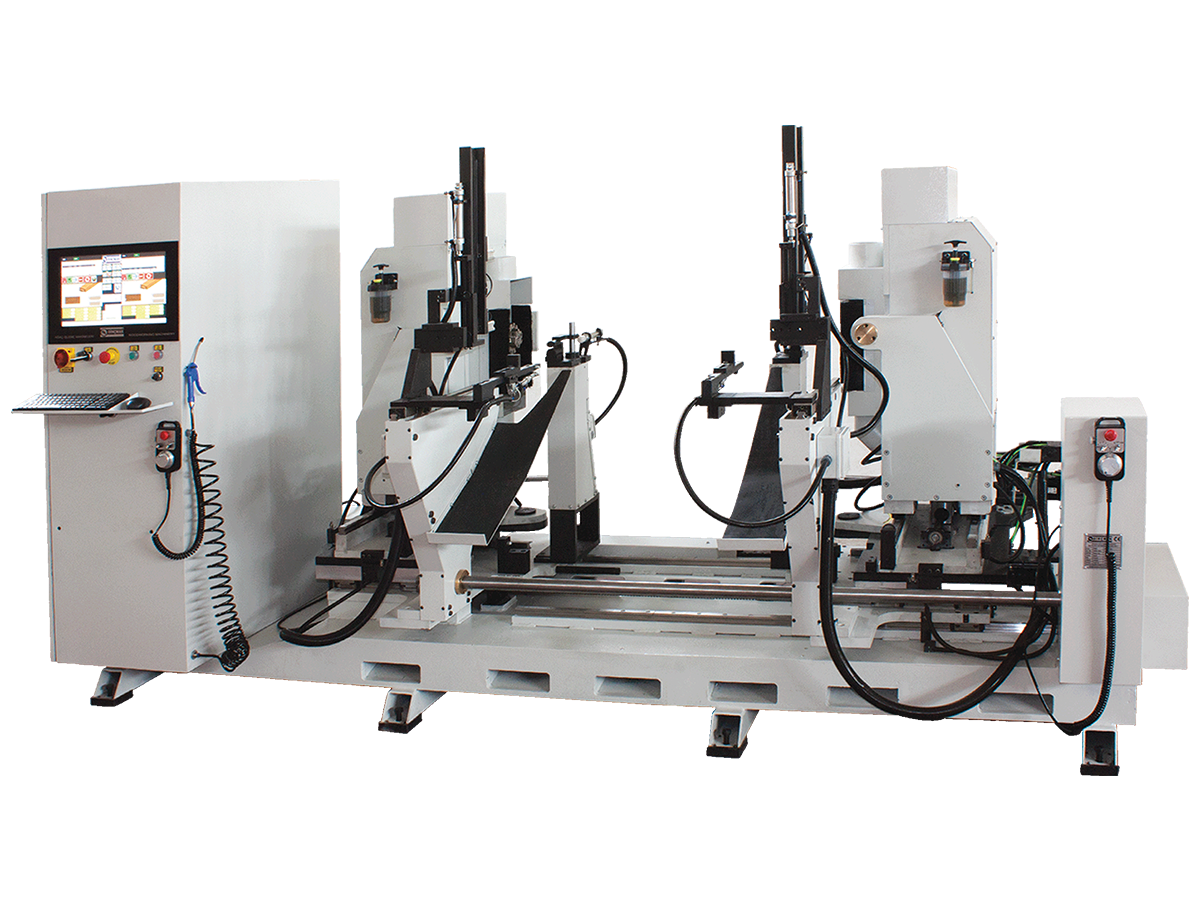

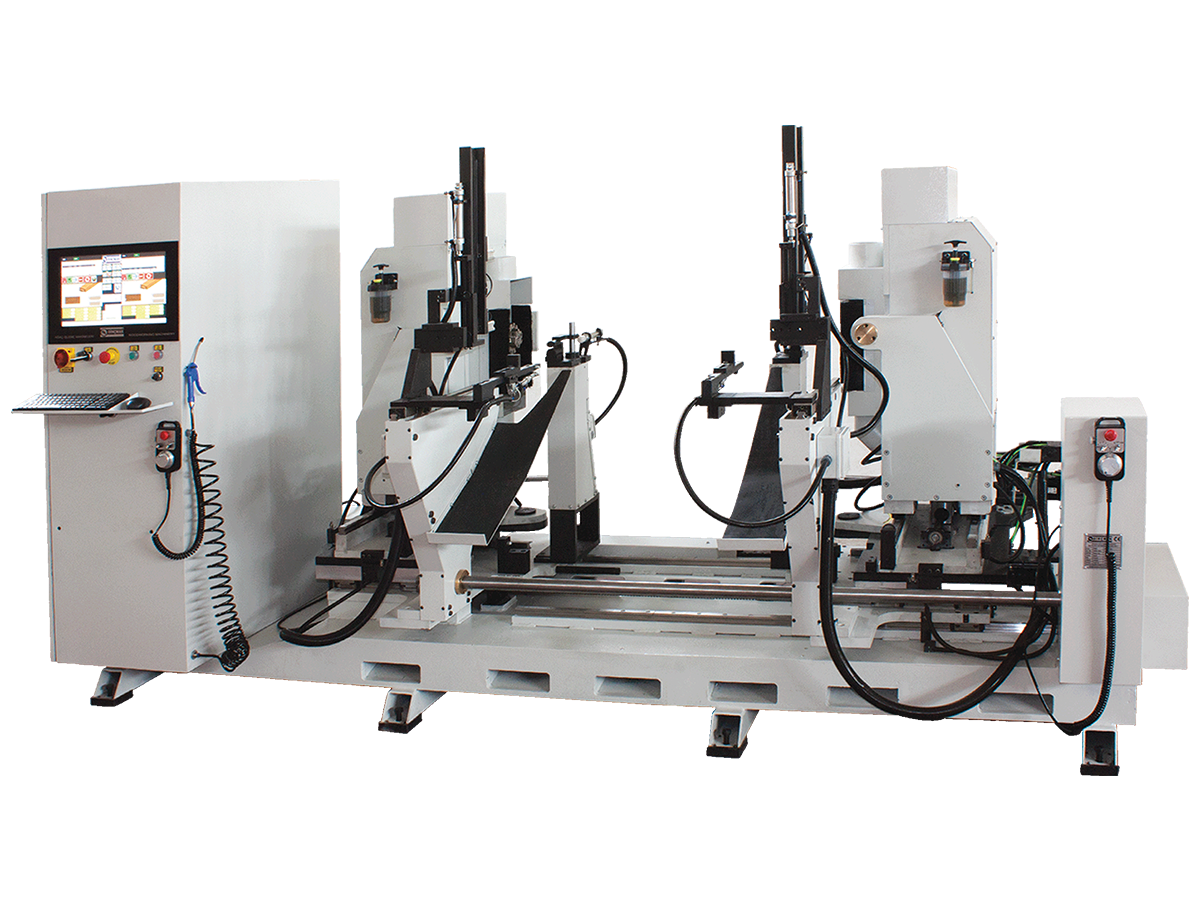

Double ends of the workpiece are processed at the same time. During the process, pneumatic grippers hold the workpiece and prevent it from losing its position. Automatic feeding unit ensures that the workpieces are transported safely to the processing center and the processed material is brought in front of the operator. With the specially developed MACRO software, tenon dimensions can be programmed parametrically and stored in memory. With the DRT.D2.CNC Tenoning machine, it is possible to make all kinds of tenon ends such as angular, round, angled and curved.

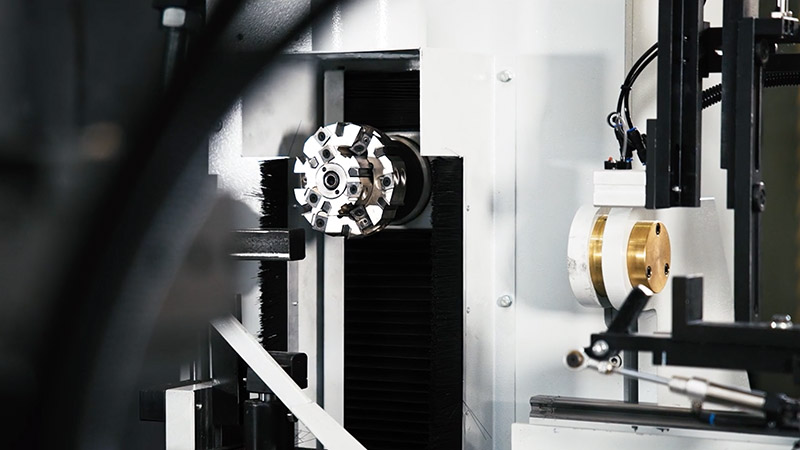

Tenoner Unit

Double ends of the workpiece are processed at the same time. During the process, pneumatic grippers hold the workpiece and prevent it from losing its position.

Automatic Feeding Unit

Thanks to the automatic feeding unit, as soon as the process is completed, the next part is driven to the machine and the finished part comes in front of the operator by the slide under the automatic feeding unit.

Software

With the specially developed MACRO software, tenon dimensions can be programmed parametrically and stored in memory.

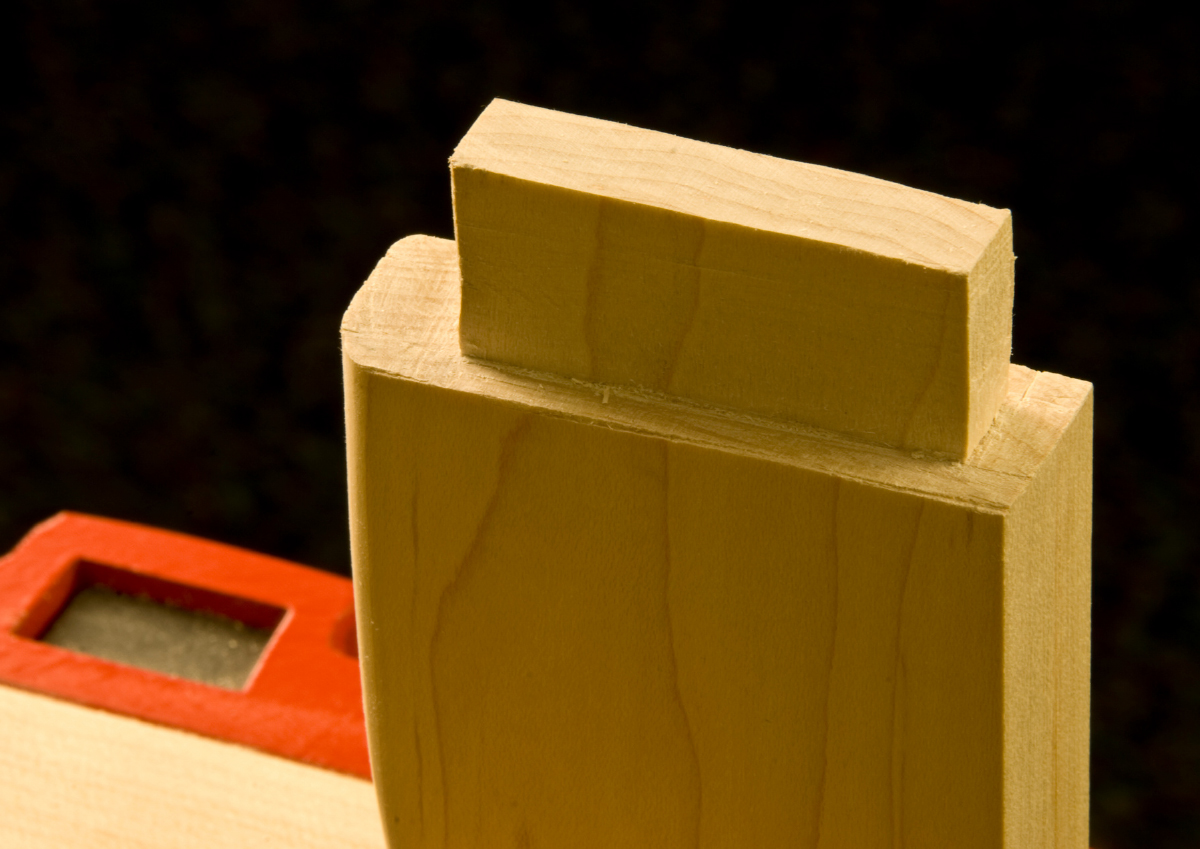

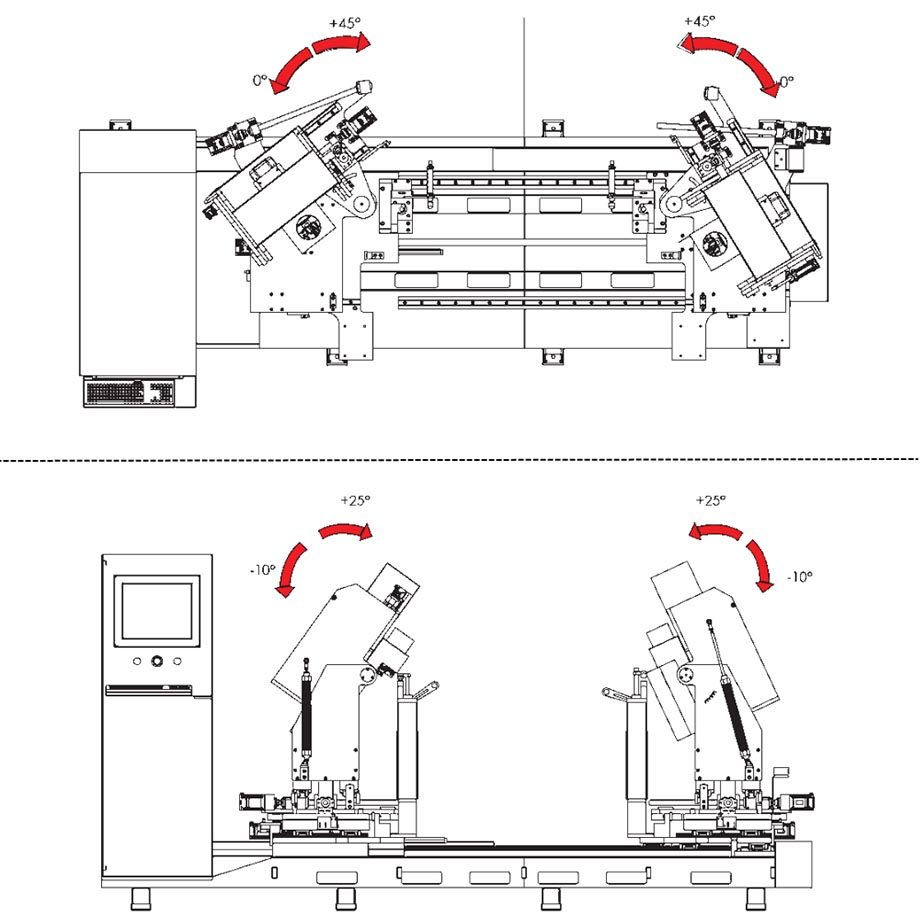

Angle Adjustment

It is possible to make all kinds of tenon ends such as angular, round, angled and curved with angularly adjustable tenoner unit.